Design Services

Design Appraisal Centre is one of fast growing Design Examination Service Providers for Mechanical and Thermal Engineering sector with enhanced expertise in Pressure Equipment Design Verification. We perform independent verification of designs & calculations to ensure compliance to various National & International Codes, Standards, and Regulations.

Our special focus has always been the constant improvement of our customer’s processes, Quality Systems to ensure Safety of people, property & environment from the Industrial hazards and detrimental effects. Personnel & quality systems at DAC are rigorously scrutinized & continuously monitored through an internal system to ensure that only the highest level of value added services are delivered to our Customers.

Preparation of Design Calculations and Drawings to meet the Statutory Compliance:

- Indian Boiler Regulation - IBR 1950 with Latest Amendments

- SMPV (Unfired) Rules 1981 – India

- Ministry of Manpower, Singapore

- Factories & Machinery (Steam Boiler and Unfired Pressure Vessels) Regulations, 1970 – DOSH, Malaysia

- Pressure Equipment Directive 2014/68/EU-European Union

- Simple Pressure Vessel Directive 2014/29/EU

- Canadian Registration Number (CRN)

- ASME Stamped Boilers and Pressure Vessels

Preparation or Verification of Design Calculations & Drawings Services for:

-

Boilers (Power & Process)

-

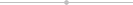

Pressure vessels : Reformers, Reactors, Multiwall Reactors, Converter Vessels, Filters, Mounded Bullets, Spheres, Autoclaves Columns

-

Storage Tanks

-

Heat Exchangers: Shell & Tube Type Heat Exchangers, Air Cooled Heat Exchangers.

-

Cryogenic Static Vessels

-

Cryogenic Transportation Vessels

-

Structures (Steel & RCC)

-

Steel Chimney & Stacks.

-

Residual Life Assesment (RLA) of in-service equipments.

Preparation or Verification of Design Calculations & Drawings Services as per following Codes & Standards

I) Boiler and Pressure vessel code (Code and non-code stamp jobs)

- ASME Sec VIII Division-1

- ASME Sec VIII Division-2 (Alternative Rules)

- AD-2000 Merkblatt

- EN-13445 (Unfired Pressure Equipment)

- EN-13458 (Cryogenic Pressure Vessel)

- EN-286 (Simple Pressure Vessel)

- PD-5500

- ISO 20703 (Gas cylinder)

- API 660 (Heat Exchanger for Refinery Service)

- TEMA Standards for Heat Exchanger

- IS 2825 (Unfired Pressure Vessel)

II) Boilers

- ASME Sec I (Power Boilers)

- IBR-1950

- EN-12952 (Water Tube Boiler)

- EN-12953 (Fire Tube Boiler)

III) Cryogenic Vessels

- Static Vessels as per ASME Sect VIII Div. 1 and SMPV Rules

- Transportation Vessels as per ASME Sec XII, EN

IV) Tanks

- API 650 (Atmospheric Storage Tanks)

- API 620 (Low Pressure Storage Tanks)

- EN-13530 (Cryogenic Tanks – Transportable)

- IS 803 (Vertical Storage Tanks for Petroleum product)

- IS 10987 (Horizontal Tanks Tanks for Petroleum product)

V) Other

- ASME Sec VIII-1, Appendix 44 Double wall tanks for cryogenics

- API-2000 (Tank Venting Requirements)

- Oil Industry Safety Directorate (OSID-116, OISD-117)

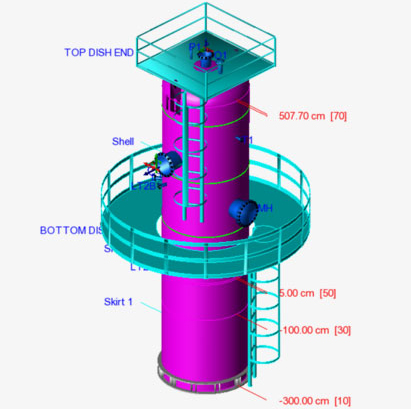

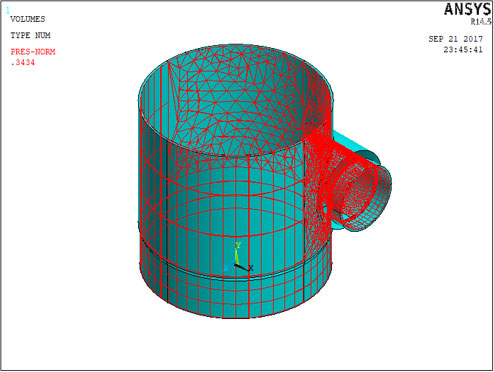

- WRC – 107 / WRC – 537 & WRC – 297 (For nozzle load analysis)

- WRC – 470 (For high temperature services)

Finite Element Analysis

- Static analysis of Pressure vessel.

- Fatigue analysis for fluctuating / alternating loads.

- Thermal analysis for the effect of operating temperature.

- Creep analysis for the evaluation in stresses at high temperature.

- Buckling analysis for stability under compressive loads / external pressure

- Self Developed Formula Based Spreadsheets for supporting calculations.

- Fitness for Service / Rerating

API 510 (In-service Inspection & rerating of Pressure Equipment)

API 579 / ASME FFS-1 (Fitness for Service)

- Gross and local corrosion

- Pitting

- Crack like flaw

- Misalignment

- Distortion

- Creep damage

- Fire damage

- Dent, gouges & combination

BOM & Purchase Indenting preparation for Material Procurement

Critical / Specialised Equipment Design Examination